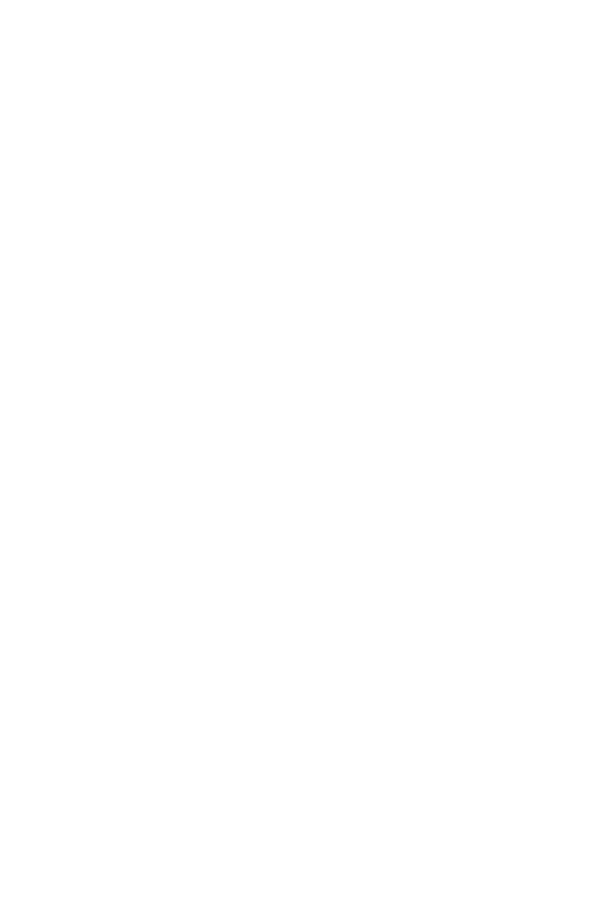

3d Prototyping

All developed in SolidWorks, 3d models were created to speed along product development. The most complex being the aluminum frame design that was an assembly of a main frame, engine / peg mount, and subframe. A coordinate measurement machine was used to determine engine case mounting points.

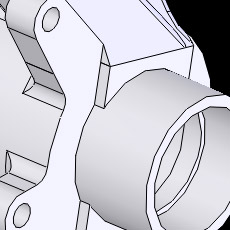

Top Left: Rear brake caliper mount.

Top Middle and Right:The 3d rendering allowed for stress testing and weight reduction prior to any machining; saving the company thousands of dollars in physical prototypes. Many, many measurements had to be specificed in the model, from the internal diameter of the integrated head tube to the mounting points of the engine. Although the subframe changed in the final production version, resembling more of a ladder frame design instead of tubing, the end result is truly unique as the chassis doesn't include a single weld.

Bottom Left: Engine cam cover with fins to help disipate heat, and represented with anodized finish.

Bottom Right: "Knuckle" for side-by-side UTV.

Digital

Lumens Rebranding

Lumens Rebranding Lumens Favorites Feature

Lumens Favorites Feature Lumens Mobile Site

Lumens Mobile Site Lumens Email Remarketing

Lumens Email Remarketing Rack N Road Website

Rack N Road Website Lumens Checkout Enhancements

Lumens Checkout Enhancements CACCU Website

CACCU Website Lumens Demandware Launch

Lumens Demandware Launch Reeg MX Website

Reeg MX Website 3d Product Modeling

3d Product Modeling

Non-digital

Reeg MX Product Line Instruction Sheets

Reeg MX Product Line Instruction Sheets Printed Works

Printed Works Clothing and Event Apparel

Clothing and Event Apparel Vehicle and Event Graphics

Vehicle and Event Graphics Print Advertisements

Print Advertisements

September 11th Memorial

September 11th Memorial Life Drawings

Life Drawings Cartooning Character Study

Cartooning Character Study Marker Sketches

Marker Sketches Marker Sketches

Marker Sketches